The performance and durability of girthflanges depend significantly on the materials used and the manufacturing processes employed. This article delves into the various materials and advanced manufacturing techniques that are used to produce high-performance girthflanges.

Common Materials for Girthflanges

- Carbon Steel: Widely used due to its strength and affordability, carbon steel girthflanges are suitable for applications where high pressure and temperature are not extreme.

- Stainless Steel: Known for its corrosion resistance and strength, stainless steel is ideal for harsh environments and applications involving corrosive substances.

- Alloy Steel: Alloy steel girthflanges offer enhanced strength and resistance to wear and tear, making them suitable for high-stress applications.

- Non-Metallic Materials: In some specialized applications, non-metallic materials like PVC and fiberglass are used for their resistance to chemicals and non-conductivity.

Advanced Manufacturing Processes

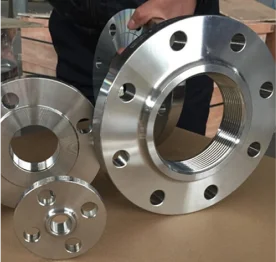

- Forging: Forging involves shaping metal using compressive forces, resulting in strong and durable girthflanges. This process enhances the mechanical properties of the material, making it ideal for high-pressure applications.

- Casting: Casting involves pouring molten metal into a mold to create the desired shape. While casting can produce complex shapes, it may not offer the same level of strength as forging.

- Machining: Precision machining is used to achieve tight tolerances and specific dimensions in girthflanges. CNC machining ensures consistency and accuracy in production.

- Welding: For some large or custom girthflanges, welding is used to join different sections. Advanced welding techniques ensure strong, leak-proof joints.

Quality Control and Testing

To ensure the reliability and performance of girthflanges, rigorous quality control and testing procedures are implemented. This includes:

- Material Testing: Verifying the composition and properties of the materials used.

- Dimensional Inspection: Ensuring that the girthflanges meet precise dimensional specifications.

- Pressure Testing: Subjecting girthflanges to high-pressure conditions to test their integrity.

- Non-Destructive Testing (NDT): Techniques like ultrasonic testing and radiography are used to detect internal flaws without damaging the girthflange.

Innovations in Girthflange Manufacturing

The field of girthflange manufacturing is continuously evolving with innovations such as:

- 3D Printing: Additive manufacturing allows for the creation of complex, custom girthflanges with reduced lead times.

- Advanced Alloys: Development of new alloy compositions to enhance performance in extreme conditions.

- Surface Treatments: Techniques like coating and plating to improve corrosion resistance and wear properties.

Conclusion

In conclusion, the materials and manufacturing processes used in the production of girthflanges significantly impact their performance and durability. Understanding the advantages and applications of different materials, such as carbon steel, stainless steel, and advanced alloys, helps in selecting the right girthflange for specific needs. Advanced manufacturing techniques like forging, casting, machining, and welding ensure high-quality girthflanges that meet stringent industry standards. Continuous innovations in materials and processes are driving the development of even more reliable and efficient girthflanges, supporting the evolving demands of industrial applications. Visit: https://www.texasflange.com/